Client story Insight Keeps Critical Healthcare Workers Connected

By Insight UK / 21 Apr 2021

A global health services organisation, this client works with healthcare professionals and other key partners to extend access to high-quality healthcare. Using innovative technology and tailored health plans to combat disease and improve patient outcomes, the client was also seeking to keep track of its users’ endpoint machines.

Insight was able to design a device management solution, ensuring the client was able to keep its vital services up and running.

The Challenge

Everyone at the company, from doctors, nurses and technologists, to customer care professionals and data scientists, work hard to make healthcare more effective and accessible.

The company’s operations team is responsible for keeping all employees equipped with the technology to fulfil their critical job roles.

As many staff work out in the field, as well as across multiple company sites, the operations team was struggling with the workload involved in simply keeping this dynamic workforce connected.

To complicate matters, an employee with a broken device could find themselves waiting weeks for a repair or replacement, resulting in long periods of downtime.

The client needed a solution to help manage its device supply chain, so it could monitor the condition of its employees’ machines and address breakdowns as soon as they happen.

The Solution

To address the client’s operational challenge, Insight offered a number of services tied into one overall supply chain solution.

Insight provided a funded head, equipped with a client-owned device, to manage device lifecycle on behalf of the client. This solved the client’s resource management issue and provided a direct connection to the supplier.

Insight’s supply chain solution also included asset tagging and imaging services, giving the asset management team key information about all end-user devices.

To avoid employees being stuck without a working machine, Insight negotiated a break/fix agreement and a hot swaps system. To ensure that this system could work smoothly without long lead times, Insight also suggested putting a buffer stock of devices in place.

Thanks to the device imaging, a user’s device image can now be quickly mapped onto a spare machine when needed. If an employees’ device breaks down, a new device, ready to use, can be shipped out on the same day. The broken device can simply be returned to the supplier for repair or disposal.

Key Benefits

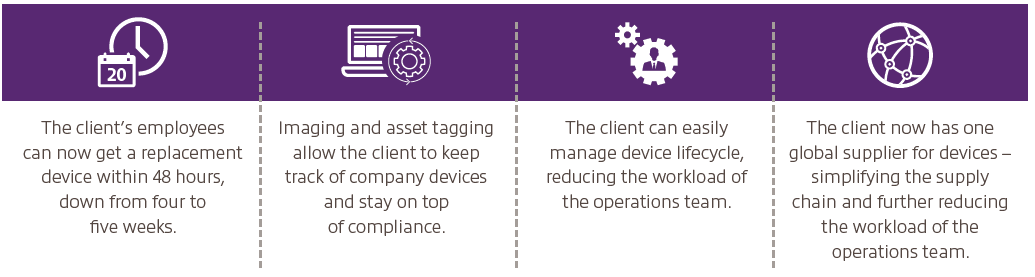

- Health professionals can quickly access support or a replacement device in the event of a breakdown.

- Downtime has been drastically cut, with deliveries that used to take between four and five weeks now being made the following day.

- The client has one global supplier for all its employees’ devices, simplifying the supply chain.

- The operations team spends less time firefighting device issues, giving them more time to add value to the business.

- The Insight solution has streamlined the client’s IT lifecycle process, and simplified reporting and compliance.

- Teams working in the field are able to get up and running more quickly when their devices break down.

The Results Highlights

Quick Overview

Client:

A global organisation providing healthcare and benefits.

Size:

The company has 300,000 employees, and customers in more than 130 countries.

Challenge:

A device supply chain solution.

Insight Solution:

Sourcing equipment, asset tagging and imaging, and breakdown support.